A pipe joint is a connecting tool between pipelines, which is a detachable connection point between components and pipelines. It plays an indispensable role in fittings and is one of the two main components of hydraulic pipelines. Pipe joints are used for straight connections such as instruments, and the connection forms include socket welding or threaded connections. Mainly used for small-diameter low-pressure pipelines, for parts that require frequent assembly and disassembly, or as the final adjustment for pipelines using threaded fittings. The structural form should adopt a metal surface contact sealing structure, and the gasket sealing structure is usually used for conveying general pipelines such as water, oil, and air, and is made of malleable cast iron material. In addition, usage requirements and price are also factors considered when selecting.

There are various types of pipe joints, and commonly used pipe joints can generally be divided into two types: hard pipe joints and flexible pipe joints. If classified according to the connection method of pipe joints and pipelines, there are three types of hard pipe joints: expansion type, sleeve type, and welding type, while hose joints are mainly compression type hose joints

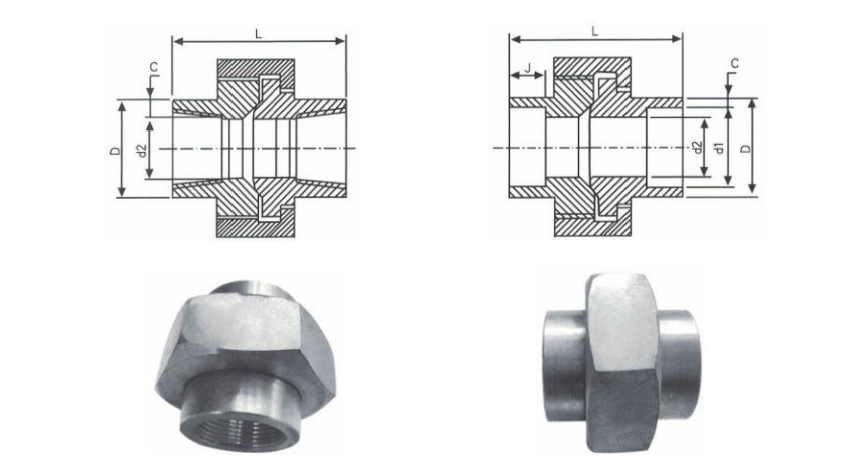

Specification:

- SW:DN15-DN100

Threaded:DN15-DN100

2. Materials:

Carbon steel flange (CS) : ASTM A105, ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65, F70;

Stainless steel flange (SS) : ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8;

Alloy flange (AS) : ASTM A182F1, F5a, F9, F11, F12, F22, F91, A182F12, A182F11, 16MnR, Cr5Mo, 12Cr1MoV, 15CrMo, 12Cr2Mo1, A335P22, ST45.8;

- Standards:

ISO5922/ISO49/ISO7-1/ISO228,EN1562:1997/EN10242:2003,DIN2950/1692/2999

ANSI/ASTM A197M-2000 ANSI/ASME16.3-92/B1.20.1-83

- Application:

Water treatment; Power plant accessories; Chemical engineering; Shipbuilding; Nuclear energy; Garbage disposal; natural gas; petroleum

| Nominal Diameter | OD | Wall thickness | Socket hole diameter | Flow diameter | Depth of socket hole | Nominal assembly length | |||

| d1 | d2 | L | |||||||

| A | B(in) | Socket | Threaded | Socket | Threaded | Socket | Socket & Threaded | Socket | Socket & Threaded |

| 6 | 1/8 | 21.8 | 14.7 | 3.2 | 2.5 | 10.65 | 6.43 | 10 | 41.4 |

| 8 | 1/4 | 21.8 | 19 | 3.3 | 3.1 | 14.1 | 9.45 | 10 | 41.4 |

| 10 | 3/8 | 25.9 | 22.9 | 3.5 | 3.2 | 17.55 | 13.51 | 10 | 46 |

| 15 | 1/2 | 31.2 | 27.7 | 4.1 | 3.8 | 21.7 | 17.07 | 10 | 49 |

| 20 | 3/4 | 37.1 | 33.5 | 4.3 | 4 | 27.05 | 21.39 | 13 | 56.9 |

| 25 | 1 | 45.5 | 41.4 | 5 | 4.6 | 33.8 | 27.74 | 13 | 62 |

| 32 | 11/4 | 54.9 | 50.5 | 5.3 | 4.9 | 42.55 | 35.36 | 13 | 71.1 |

| 40 | 11/2 | 61.5 | 57.2 | 5.6 | 5.1 | 48.65 | 41.2 | 13 | 76.5 |

| 50 | 2 | 75.2 | 70.1 | 6.1 | 5.6 | 61.1 | 52.12 | 16 | 86.1 |

| 65 | 21/2 | 91.7 | 85.3 | 7.7 | 7.1 | 73.8 | 64.31 | 16 | 102.4 |

| 80 | 3 | 109.2 | 102.4 | 8.4 | 7.7 | 89.8 | 77.27 | 16 | 109 |