Blind flange, also known as flange blind or blind flange, is a type of flange connection without a hole in the middle, mainly used for sealing pipeline ends or isolating systems.

Definition and Structure

Basic features: Blind flange is a solid circular metal sheet without a central hole, fixed to the flange surface of the pipeline by bolts, forming a sealed isolation.

Function and purpose

Sealing and isolation: used to permanently or temporarily seal the end of a pipeline, or to isolate fluids during maintenance to ensure safe operation.

Compared to other components: Similar in function to the head and pipe cap, but the blind flange is detachable and has higher flexibility.

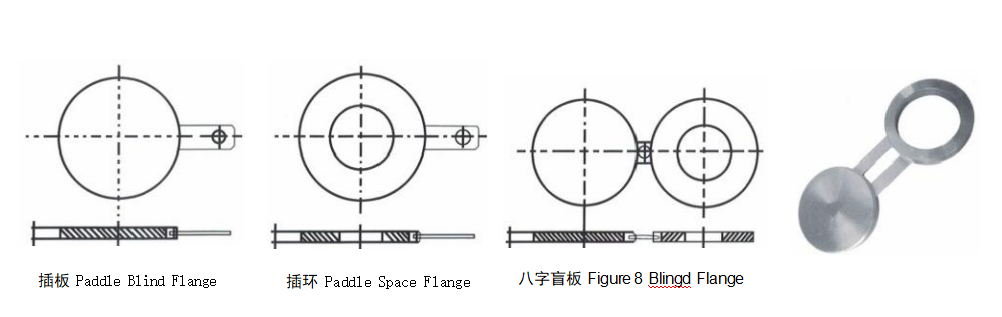

Special type: such as an 8-shaped blind plate, with one end as a blind plate and the other end as a throttling ring, making it easy to switch between isolation and normal operation.

Material and sealing form

Common materials: carbon steel (such as Q235), stainless steel, alloy steel, plastic (PVC/PPR), etc., choose according to the medium and pressure.

Sealing surface design: including flat (FF), convex (RF), concave convex (MFM), mortise and tenon (TG), etc., to meet different sealing requirements.

Application scenarios

Maintenance and safety: Isolate the system during equipment maintenance and pipeline strength testing to prevent medium leakage.

System expansion: Provide temporary closure for reserved interfaces for future pipelines.

Multiple series devices: Blind plates are installed at the bifurcation of the boundary pipeline to achieve independent control.

Specification:

- Sizes:1/2”-120”;DN15-DN3000

Materials: Carbon steel flange (CS) : ASTM A105, ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65, F70;

Stainless steel flange (SS) : ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8;

Alloy flange (AS) : ASTM A182F1, F5a, F9, F11, F12, F22, F91, A182F12, A182F11, 16MnR, Cr5Mo, 12Cr1MoV, 15CrMo, 12Cr2Mo1, A335P22, ST45.8;

- Standards:

ASME B16.5; HG20592; DIN2527、2573、2627-2638、2673、2552、2653、2655、2656、2641、2642、2565-2569; GOST12820; JIS B2220

- Application:

Water treatment; Power plant accessories; Chemical engineering; Shipbuilding; Nuclear energy; Garbage disposal; natural gas; petroleum

| Nominal Sze DN |

NPS | 150LB | 300LB | 600LB | 900LB | 1500LB | 2500LB | Nominal Size DN |

0.6MPa | 1.0MPa | 1.6MPa | 2.5MPa | 4.0MPa | |

| 2.0MPa | 5.0MPa | 10.0MPa | 15.0MPa | 25.0MPa | 42.0MPa | |||||||||

| 15 | 1/2 | 3 | 6 | 6 | 6 | 6 | 10 | |||||||

| 20 | 3/4 | 3 | 6 | 6 | 6 | 0 | 10 | 15 | 8 | 8 | 8 | 8 | 8 | |

| 25 | 1 | 3 | 6 | 6 | 6 | 10 | 10 | 20 | 8 | 8 | 8 | 8 | 8 | |

| 32 | 1.1/4 | 6 | 6 | 10 | 10 | 10 | 13 | 25 | 8 | 8 | 8 | 8 | 9/8 | |

| 40 | 1.1/2 | 6 | 6 | 10 | 10 | 13 | 16 | 32 | 8 | 8 | 8 | 8 | 10/8 | |

| 50 | 2 | 6 | 10 | 10 | 13 | 13 | 16 | 40 | 8 | 8 | 8 | 9/8 | 10/8 | |

| 65 | 2.1/2 | 6 | 10 | 13 | 13 | 16 | 19 | 50 | 8 | 8 | 9/8 | 10/8 | 12/10 | |

| 80 | 3 | 6 | 10 | 13 | 16 | 19 | 22 | 65 | 8 | 8 | 10/8 | 11/9 | 13/11 | |

| 90 | 3.1/2 | 10 | 13 | 16 | 80 | 8 | 8 | 10/8 | 12/10 | 14/12 | ||||

| 100 | 4 | 10 | 13 | 16 | 19 | 22 | 28 | 100 | 10/8 | 8 | 12/10 | 14/12 | 16/14 | |

| 125 | 5 | 10 | 16 | 19 | 22 | 28 | 35 | 125 | 11/9 | 9/8 | 13/11 | 16/14 | 19/17 | |

| 150 | 6 | 13 | 16 | 22 | 25 | 35 | 41 | 150 | 12/10 | 10/8 | 15/13 | 17/15 | 21/19 | |

| 200 | 8 | 13 | 22 | 28 | 35 | 41 | 54 | 200 | 14/12 | 12/10 | 17/15 | 21/19 | 27/25 | |

| 250 | 10 | 16 | 25 | 35 | 41 | 51 | 67 | 250 | 17/15 | 13/11 | 20/18 | 25/23 | 32/30 | |

| 300 | 12 | 19 | 28 | 41 | 48 | 60 | 79 | 300 | 19/17 | 15/13 | 23/21 | 29/27 | 37/35 | |

| 350 | 14 | 19 | 32 | 44 | 54 | 67 | 350 | 21/19 | 17/15 | 26/24 | 33/31 | 42/40 | ||

| 400 | 16 | 22 | 38 | 51 | 60 | 76 | 400 | 23/21 | 18/16 | 29/27 | 36/34 | 48/46 | ||

| 450 | 18 | 25 | 41 | 54 | 67 | 86 | 450 | 25/23 | 20/18 | 32/30 | 39/37 | 50/48 | ||

| 500 | 20 | 28 | 44 | 64 | 73 | 95 | 500 | 28/26 | 22/20 | 35/33 | 43/41 | 54/52 | ||

| 600 | 24 | 32 | 51 | 73 | 89 | 111 | 600 | 32/30 | 25/23 | 41/39 | 51/49 | 65/62 | ||

| explain: | explain: | |||||||||||||

| 1. This series of products complies with API590 requirements and is used for raised face flanges that meet the following requirements: ANSIB16.5, SH3406, SO7005-1, GB9112-9124, HG20615 (American system). | 1. This series of products meets the requirements of HG21547-93 and is used for protruding flanges that meet the following requirements: GB9113-9122, HG20592 (European system), ISO7005-1, DIN, JB pipe flanges. | |||||||||||||

| 2. The thickness of blind plates, insert rings, and eight shaped blind plates all include corrosion allowance: the allowance for carbon steel, low-alloy steel, and low-temperature steel is 13mm; Stainless steel allowance is 0mm | 2. The thickness of blind plates, insert rings, and eight shaped blind plates all include corrosion allowance: carbon steel, low-alloy steel, and low-temperature steel allowance of 2.0mm; The stainless steel allowance is 0mm. The above table contains numerator/denominator, where the numerator represents the thickness of carbon steel and low-alloy steel, and the denominator represents the thickness of stainless steel. | |||||||||||||

| 3. This series of products is suitable for flat gaskets. If used for other types of gaskets (such as octagonal gaskets, etc.), the manufacturer should be consulted and the thickness adjusted. | 3. This series of products is suitable for flat gaskets. If used for other types of gaskets (such as octagonal gaskets, etc.), the manufacturer should be consulted and the thickness adjusted. | |||||||||||||

| 4. It can also be produced according to the requirements of HG21547-93. | ||||||||||||||