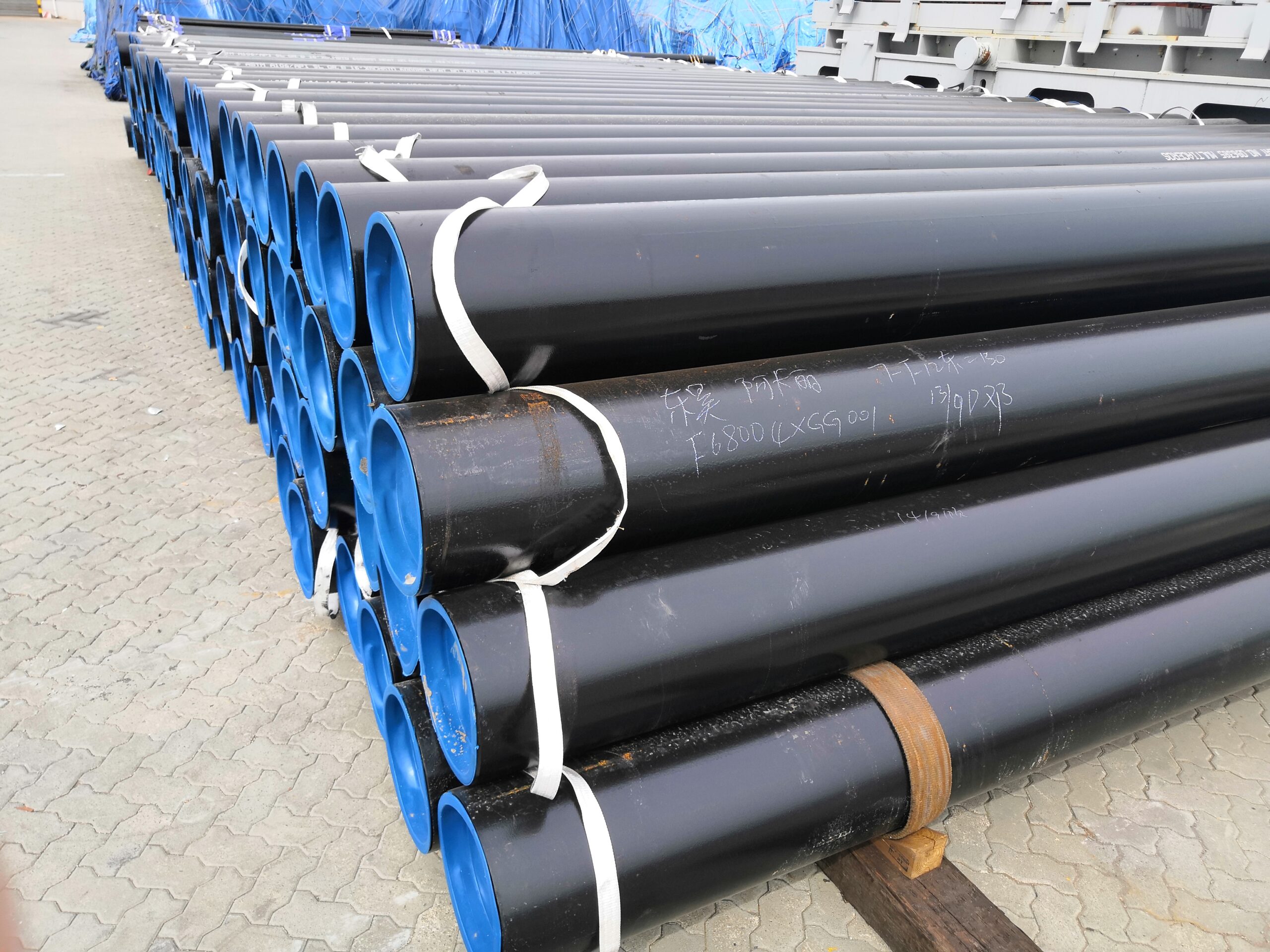

Anti corrosion coasting steel pipe refers to a steel pipeline that has been processed and treated with anti-corrosion technology to effectively prevent or slow down the occurrence of chemical or electro chemical reactions and corrosion during transportation and use.

The anti-corrosion of steel pipes not only improves their service life, but also manifests in the following aspects:

1. Combining the mechanical strength of steel pipes with the corrosion resistance of plastics;

2. The outer wall coating is over 2.5mm, scratch resistant and collision resistant;

3. The inner wall friction coefficient is small, ranging from 0.0081 to 0.091, which reduces energy consumption;

4. The inner wall meets the national hygiene standards;

5. The inner wall is smooth and not prone to scaling, and has self-cleaning function.

Specification:

Diameter and wall thickness

Common diameters: 20mm, 25mm, 32mm, 50mm, 108mm, 219mm, 273mm, 325mm, etc., with a maximum diameter of 3020mm (for special projects).

Wall thickness range: 1.0mm~25mm, specifically 1.0mm, 1.5mm, 2.0mm, 2.5mm, 8mm, 10mm, 12mm, etc. The wall thickness of large-diameter steel pipes is usually thicker.

Length

The standard length is generally 6m, 9m, and 12m, and some projects can be customized according to requirements.

Material

Common carbon steel materials include Q195, Q235, Q345, and 20 #, 35 #, 45 #, etc. Different materials are suitable for different strength and corrosion resistance requirements.

Anti corrosion types and applicable scenarios

3PE anti-corrosion: commonly used for large water and oil and gas pipelines, such as spiral steel pipes with diameters ranging from 219mm to 3020mm.

IPN8710 anti-corrosion: suitable for complex corrosive environments such as acid, alkali, salt, etc., such as the inner wall of water supply pipelines.

FBE epoxy powder anti-corrosion: resistant to high temperature and impact, commonly used in chemical pipelines.

Coated steel pipe advantages

Coating steel pipes are fully automatic coated by machines, with good coating adhesion; the thickness of the graphical layer pipe can be customized; our products are tested by electric spark online to ensure that there are no leaks in the coating; there are also five production lines, with fast delivery time.