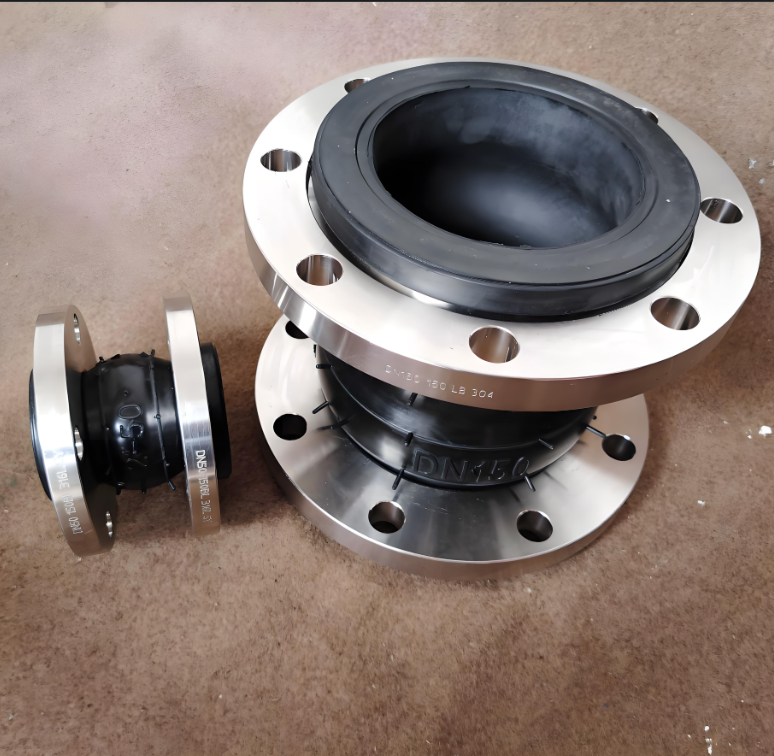

A flange rubber damper (also known as a flange rubber shock absorber, flange rubber joint, or soft connection) is a damping element designed specifically for industrial pipeline systems. It absorbs vibration energy and compensates for displacement through the elastic deformation of rubber. Its core structure and function are as follows:

Main material

Rubber part: Nitrile rubber (NBR) is usually used for oil resistance, chloroprene rubber (CR) for weather resistance, ethylene propylene diene monomer (EPDM) for corrosion resistance, or silicone rubber for high temperature resistance. The formula can be customized according to the characteristics of the medium.

Metal skeleton: The flange part is mostly made of carbon steel or stainless steel, which is tightly bonded with rubber through vulcanization process to ensure mechanical strength and sealing.

Typical structure

Ripple/groove design: enhances the elastic deformation ability of rubber and optimizes multi-directional vibration reduction effect.

Bowl shaped/spherical structure: Some models use bowl shaped curved surfaces to distribute loads, compact and multi-directional vibration isolation (such as bowl shaped rubber shock absorbers)

Specifications:

Pressure: 1.0MP-1.6MPa

Applicable media: water and acidic/alkaline liquids

Applicable temperature: -10 ° C-120 ° C

Material: Stainless steel, carbon steel, cast iron, etc.

| Nominal DiameterDN | Length(mm) | Compression(mm) | Stretch(mm) | Displacement(mm) | Deflection ° |

| 25 | 95 | 8 | 4 | 8 | 15 |

| 32 | 95 | 8 | 4 | 8 | 15 |

| 40 | 95 | 8 | 5 | 10 | 15 |

| 50 | 105 | 8 | 5 | 10 | 15 |

| 65 | 115 | 12 | 6 | 12 | 15 |

| 80 | 135 | 12 | 6 | 12 | 15 |

| 100 | 150 | 18 | 10 | 12 | 15 |

| 125 | 165 | 18 | 10 | 15 | 15 |

| 150 | 180 | 18 | 10 | 15 | 15 |

| 200 | 210 | 25 | 14 | 15 | 15 |

| 250 | 230 | 25 | 14 | 15 | 15 |

| 300 | 245 | 25 | 14 | 15 | 15 |

| 350 | 255 | 25 | 15 | 22 | 15 |

| 400 | 255 | 25 | 15 | 22 | 12 |

| 450 | 255 | 25 | 15 | 22 | 12 |

| 500 | 255 | 25 | 16 | 22 | 12 |

| 600 | 260 | 25 | 16 | 22 | 12 |

| 700 | 260 | 25 | 16 | 22 | 12 |