Plate flange connection is the process of fixing two pipes, fittings, or equipment onto a flange plate, adding flange pads between the two flanges, and fastening them together with bolts to complete the connection. Some pipe fittings and equipment already come with flanges, which also belong to flange connections. Plate flange connection is an important connection method in pipeline construction. The flange connection is easy to use and can withstand high pressure. In industrial pipelines, flange connections are widely used. In the home, the diameter of the pipeline is small and it is low-pressure, so flange connections cannot be seen. If there are flanged pipes and equipment everywhere in a boiler room or production site.

Compared to neck flanges, flat flanges can be divided into carbon steel flat flanges, stainless steel flat flanges, and alloy steel flat flanges based on their materials. The structural forms of flanges include integral flanges and unit flanges.

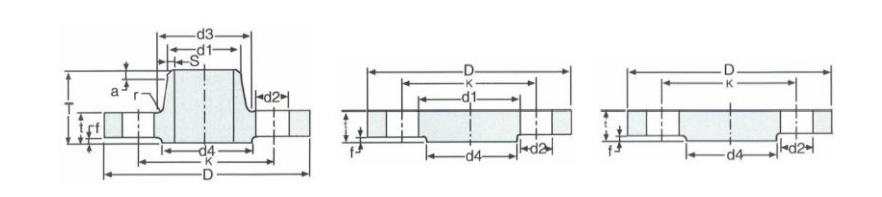

Specification:

- Sizes:1/2”-120”;DN15-DN3000

- Materials:

Carbon steel flange (CS) : ASTM A105, ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65, F70;

Stainless steel flange (SS) : ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8;

Alloy flange (AS) : ASTM A182F1, F5a, F9, F11, F12, F22, F91, A182F12, A182F11, 16MnR, Cr5Mo, 12Cr1MoV, 15CrMo, 12Cr2Mo1, A335P22, ST45.8;

- Standards:

ASME B16.5; HG20592; DIN2527、2573、2627-2638、2673、2552、2653、2655、2656、2641、2642、2565-2569; GOST12820; JIS B2220

- Application:

Water treatment; Power plant accessories; Chemical engineering; Shipbuilding; Nuclear energy; Garbage disposal; natural gas; petroleum

| 16BAR | ||||||||||||||||||

| Bore | Common Dimention | Welding Neck | Raised Face | Driling | Approx Weght(kg) | |||||||||||||

| Norminal Bore |

d1 | D | WekingNeck | t | K | T | d3 | s | a | d4 | f | Number of Bolt | Daof Bot | d2 | DIN 5276 | DIN 2632 | ||

| Slop-on | Bild | |||||||||||||||||

| 10A | 14) 17.2* | 90 | 14 | 14 | 60 | 35 | 25 | 1.8 | 4 | 6 | 40 | 2 | 4 | M12(12) | 14 | 0.63 | 0.58 | |

| 28 | ||||||||||||||||||

| 15A | 20) 21.3* | 95 | 14 | 14 | 14 | 65 | 35 | 30 | 2 | 4 | 6 | 45 | 2 | 4 | M12(12”) | 14 | 0.72 | 0.648 |

| 32 | ||||||||||||||||||

| 20A | 25 26.9* | 105 | 16 | 16 | 16 | 75 | 38 | 38 | 2.3 | 4 | 6 | 58 | 2 | 4 | M12(12″) | 14 | 1.01 | 0.952 |

| 40 | ||||||||||||||||||

| 25A | 30 33.7* | 115 | 16 | 16 | 16 | 85 | 38 | 42 | 2.6 | 4 | 6 | 68 | 2 | 4 | M12(12″) | 14 | 1.23 | 1.14 |

| 45 | ||||||||||||||||||

| 32A | 38 42.4 | 140 | 16 | 16 | 16 | 100 | 40 | 52 | 26 | 6 | 6 | 78 | 2 | 4 | M16(58″) | 18 | 1.8 | 1.69 |

| 56 | ||||||||||||||||||

| 40A | 42.4 | 150 | 16 | 16 | 16 | 110 | 42 | 60 | 2.6 | 6 | 7 | 88 | 3 | 4 | M16(58″) | 18 | 2.09 | 1.86 |

| 44.5 48.3* | 64 | |||||||||||||||||

| 50A | 57 | 165 | 18 | 18 | 18 | 125 | 45 | 72 | 2.9 | 6 | 8 | 102 | 3 | 4 | M16(58”) | 18 | 2.88 | 2.53 |

| 65A | 60.3* | 185 | 18 | 18 | 18 | 145 | 45 | 75 | 2.9 | 6 | 10 | 122 | 3 | 4 | M16(58″) | 18 | 3.66 | 3.06 |

| 80A | 76.1 | 200 | 20 | 20 | 20 | 160 | 50 | 90 | 3.2 | 8 | 10 | 158 | 3 | 8 | M16(587) | 18 | 4.77 | 3.7 |

| 88.9* | 105 | |||||||||||||||||

| 100A | 108 | 220 | 20 | 20 | 20 | 180 | 52 | 125 | 3.6 | 8 | 12 | 158 | 3 | 8 | M16(58”) | 18 | 5.65 | 4.62 |

| 114.3* | 31 | |||||||||||||||||

| 125A | 133 | 250 | 22 | 22 | 22 | 210 | 55 | 50 | 40 | 8 | 12 | 188 | 3 | 8 | M16(58”) | 18 | 8.42 | 6.3 |

| 139.7* | 156 | |||||||||||||||||

| 150A | 159 | 285 | 24 | 22 | 22 | 240 | 55 | 175 | 4.5 | 10 | 12 | 212 | 3 | 8 | M2O(34″) | 23 | 10.4 | 7.75 |

| 168.3* | 184 | |||||||||||||||||

| 200A | 216 | 340 | 24 | 24 | 24 | 295 | 62 | 232 | 5.9 | 10 | 16 | 268 | 3 | 12 | M20(34″) | 23 | 16.1 | 11 |

| 219.1* | 235 | |||||||||||||||||

| 250A | 267 | 405 | 26 | 26 | 26 | 355 | 70 | 285 | 6.3 | 12 | 16 | 320 | 3 | 12 | M24(7/8″) | 27 | 24.9 | 15.6 |

| 273* | 292 | |||||||||||||||||

| 300A | 318 | 460 | 28 | 28 | 28 | 410 | 78 | 338 | 7.1 | 12 | 16 | 378 | 4 | 12 | M24(7/8″) | 27 | 35.1 | 22 |

| 323.9* | 344 | |||||||||||||||||

| 350A | 3556* 368 | 520 | 30 | 30 | 30 | 470 | 82 | 390 | 8 | 12 | 16 | 438 | 4 | 16 | M24(7/8”) | 27 | 47.8 | 28.7 |

| 400A | 406.4* 419 | 580 | 32 | 32 | 32 | 525 | 85 | 445 | 8 | 12 | 16 | 490 | 4 | 16 | M27(1″) | 30 | 63.5 | 36.3 |

| 500A | 508*521 | 715 | 34 | 38 | 34 | 650 | 90 | 548 | 8 | 12 | 16 | 610 | 4 | 20 | M30(11/8”) | 33 | 102 | 59.3 |

| 600A | 609.6* | 840 | 36 | 40 | 770 | 95 | 652 | 8.8 | 12 | 18 | 725 | 5 | 20 | M33(114″) | 36 | |||

| 622 | ||||||||||||||||||

| 700A | 7112 | 910 | 36 | 840 | 100 | 755 | 8.8 | 12 | 18 | 795 | 5 | 24 | M33(1/4”) | 36 | ||||

| 720 | ||||||||||||||||||

| 800A | 812.8* 820 | 1025 | 38 | 950 | 105 | 855 | 10 | 12 | 20 | 900 | 5 | 24 | M36(138″) | 39 | ||||

| 900A | 914.4* | 1125 | 40 | 1050 | 110 | 955 | 10 | 12 | 20 | 1000 | 5 | 28 | M36(138″) | 39 | ||||

| 920 | ||||||||||||||||||

| 1000A | 1016* | 1255 | 42 | 1170 | 120 | 1058 | 10 | 16 | 20 | 1115 | 5 | 28 | M39(11/2″) | 42 | ||||

| 1020 | ||||||||||||||||||

| NOTE*Out side diameter of pipe complied with ISO recommendation R64 | ||||||||||||||||||