Flanges, also known as flange discs or flanges. A flange is a component that connects shafts to each other and is used for connecting pipe ends; Also used for flanges on equipment imports and exports, used for connecting two devices, such as gearbox flanges. Flange connection or flange joint refers to a detachable connection in which a flange, gasket, and bolt are connected to each other as a combined sealing structure. Pipeline flange refers to the flange used for piping in pipeline installations, and when used on equipment, it refers to the inlet and outlet flanges of the equipment. There are holes on the flange, and bolts tightly connect the two flanges. Seal the flanges with gaskets. Flanges are divided into threaded connections (threaded connections), welded flanges, and clamp flanges. Flanges are used in pairs. For low-pressure pipelines, threaded flanges can be used, while for pressures above four kilograms, welded flanges can be used. Add a sealing gasket between the two flanges and tighten them with bolts. The thickness of flanges under different pressures varies, and the bolts used are also different. When connecting water pumps and valves to pipelines, the corresponding flange shapes are also made for the parts of these equipment, also known as flange connections. Any connecting component that uses bolts to connect and seal two planes together is generally referred to as a “flange”, such as the connection of ventilation ducts, which can be called a “flange type component”. However, this connection is only a partial part of a device, such as the connection between a flange and a water pump, so it is not appropriate to call the water pump a “flange type component”.

Category:

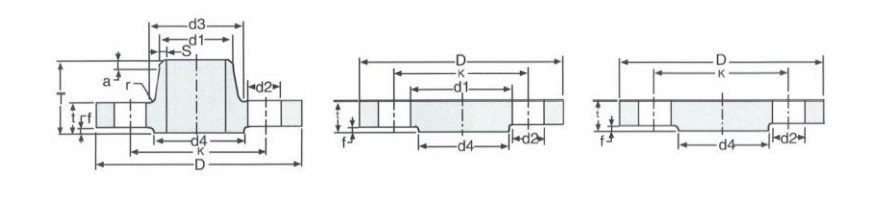

According to the standards of the chemical (HG) industry, it can be divided into: integral flange (IF), threaded flange (Th), plate flat welding flange (PL), neck butt welding flange (WN), neck flat welding flange (SO), socket welding flange (SW), butt welding ring loose flange (PJ/SE), and flat welding ring loose flange (PJ/RJ)。

Connection method:

A flange connection is the process of first fixing two pipes, fittings, or equipment onto a flange, then adding a flange gasket between the two flanges and fastening them together with bolts to complete the connection. Some pipe fittings and equipment already come with flanges, which also belong to flange connections. Flange connection is an important connection method in pipeline construction. The flange connection is easy to use and can withstand high pressure. In industrial pipelines, in households, the diameter of the pipeline is small and it is low-pressure, so flange connections cannot be seen. If there are flanged pipes and equipment everywhere in a boiler room or production site. [1]

According to the connection method, flange connection types can be divided into: plate flat welding flange, neck flat welding flange, neck butt welding flange, socket welding flange, threaded flange, flange cover, neck butt welding ring loose sleeve flange, flat welding ring loose sleeve flange, ring groove surface flange and flange cover, large diameter flat plate flange, large diameter high neck flange, eight shaped blind plate, butt welding ring loose sleeve flange, etc

Specification:

- Sizes:1/2”-120”;DN15-DN3000

- Materials:

Carbon steel flange (CS) : ASTM A105, ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65, F70;

Stainless steel flange (SS) : ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8;

Alloy flange (AS) : ASTM A182F1, F5a, F9, F11, F12, F22, F91, A182F12, A182F11, 16MnR, Cr5Mo, 12Cr1MoV, 15CrMo, 12Cr2Mo1, A335P22, ST45.8;

- Standards:

ASME B16.5; HG20592; DIN2527、2573、2627-2638、2673、2552、2653、2655、2656、2641、2642、2565-2569; GOST12820; JIS B2220

| 10A | 14) 17.2* | 90 | 4 | 6 | 40 | 2 | 4 | M12(12) |

| 15A | 20) 21.3* | 95 | 4 | 6 | 45 | 2 | 4 | M12(12”) |

| 20A | 25 26.9* | 105 | 4 | 6 | 58 | 2 | 4 | M12(12″) |

| 25A | 30 33.7* | 115 | 4 | 6 | 68 | 2 | 4 | M12(12″) |

| 32A | 38 42.4 | 140 | 6 | 6 | 78 | 2 | 4 | M16(58″) |