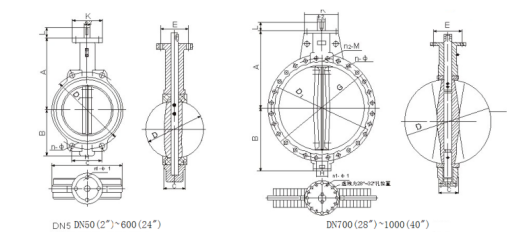

The disc of the wafer butterfly valve is installed in the diameter direction of the pipeline. In the cylindrical channel of the butterfly valve body, the disc-shaped butterfly plate rotates around the axis, and the rotation angle is between 0° and 90°. When it rotates to 90°, the valve is fully open. This valve is generally installed horizontally. The wafer butterfly valve is simple in structure, small in size and light in weight, and only consists of a few parts. And it only needs to rotate 90° to open and close quickly, the operation is simple, and the valve has good fluid control characteristics. When the butterfly valve is in the fully open position, the thickness of the disc is the only resistance when the medium flows through the valve body, so the pressure drop generated by the valve is very small, so it has better flow control characteristics

Specification:

- Sizes: Seamless Size:DN15-DN1200

Welded Size:DN200-DN2000

- Thickness:SCH10;SCH20;SCH30;STD;SCH40;SCH60;SCH80;SCH100;SCH120;SCH160;XS;XXS; Max 150mm

- Materials:

Carbon steel flange (CS) : ASTM A105, ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65, F70;

Stainless steel flange (SS) : ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8;

Alloy flange (AS) : ASTM A182F1, F5a, F9, F11, F12, F22, F91, A182F12, A182F11, 16MnR, Cr5Mo, 12Cr1MoV, 15CrMo, 12Cr2Mo1, A335P22, ST45.8;

- Standards:

ASME B16.9; GB12459; DIN2616; GOST17378-2001; JIS B2311

- Application:

Water treatment; Power plant accessories; Chemical engineering; Shipbuilding; Nuclear energy; Garbage disposal; natural gas; petroleum

| Norminal Diameters | Size(mm) | Norminal Diameters Size(mm) | Weight(kg) | |||||||||||||

| mm | inch | A | B | C | D | L | H | D1 | n-∅ | K | E | ni-∅1 | ∅2 | G | n2-M | |

| 50 | 2″ | 161 | 80 | 42 | 52.9 | 32 | 84.84 | 120 | 4-23 | 77 | 57.15 | 4-6.7 | 12.6 | 118 | – | 2.5 |

| 65 | 2.5″ | 175 | 89 | 44.7 | 64.5 | 32 | 96.2 | 136 | 4-26.5 | 77 | 57.15 | 4-6.7 | 12.6 | 137 | – | 3.2 |

| 80 | 3″ | 181 | 95 | 45.2 | 78.8 | 32 | 61.23 | 160 | 8-18 | 77 | 57.15 | 4-6.7 | 12.6 | 143 | – | 3.6 |

| 100 | 4″ | 200 | 114 | 52.1 | 104 | 32 | 70.8 | 185 | 4-24.5 | 92 | 69.85 | 4-10.3 | 15.77 | 156 | – | 4.9 |

| 125 | 5″ | 213 | 127 | 54.4 | 123.3 | 32 | 82.28 | 215 | 4-23 | 92 | 69.85 | 4-10.3 | 18.92 | 190 | – | 7 |

| 150 | 6″ | 226 | 139 | 55.8 | 155.6 | 32 | 91.08 | 238 | 4-25 | 92 | 69.85 | 4-10.3 | 18.92 | 212 | – | 7.8 |

| 200 | 8″ | 260 | 175 | 60.6 | 202.5 | 45 | 112.89 | 295 | 4-25 | 115 | 88.9 | 4-14.3 | 22.1 | 268 | – | 13.2 |

| 76.35 | 4-23 | |||||||||||||||

| 250 | 10″ | 292 | 203 | 65.6 | 250.5 | 45 | 92.4 | 357 | 4-29 | 115 | 88.9 | 4-14.3 | 28.45 | 325 | – | 19.2 |

| 300 | 12″ | 337 | 242 | 76.9 | 301.6 | 45 | 105.34 | 407 | 4-29 | 140 | 107.95 | 4-14.3 | 31.6 | 403 | – | 32.5 |

| 350 | 14″ | 368 | 267 | 76.5 | 333.3 | 45 | 91.11 | 467 | 4-30 | 140 | 107.95 | 4-14.3 | 31.6 | 438 | – | 41.3 |

| 400 | 16″ | 400 | 309 | 86.5 | 389.6 | 51.2 | 100.47 | 515 | 4-26 | 197 | 158.74 | 4-20.6 | 33.15 | 488 | – | 61 |

| 72 | 102.42 | 525 | 4-30 | |||||||||||||

| 450 | 18″ | 422 | 328 | 106 | 440.51 | 51.2 | 88.39 | 565 | 4-26 | 197 | 158.75 | 4-20.6 | 38 | 539 | – | 79 |

| 72 | 91.51 | 585 | 4-30 | |||||||||||||

| 500 | 20″ | 480 | 361 | 132 | 491.6 | 64.2 | 96.99 | 620 | 4-26 | 197 | 158.75 | 4-20.6 | 41.15 | 593 | – | 128 |

| 82 | 101.68 | 650 | 4-33 | |||||||||||||

| 600 | 24″ | 562 | 459 | 152 | 592.5 | 70.2 | 113.42 | 725 | 20-30 | 276 | 215.9 | 4-22.2 | 50.65 | 816 | – | 188 |

| 82 | 120.46 | 770 | 20-36 | |||||||||||||

| 700 | 28″ | 624 | 520 | 163 | 695 | 66 | 109.7 | 840 | 24-33 | 300 | 254 | 8-18 | 55 | 895 | 4-M33 | 284 |

| 82 | 20-39 | 63.35 | ||||||||||||||

| 800 | 32″ | 672 | 591 | 188 | 794.7 | 66 | 124 | 950 | 24-33 | 300 | 254 | 8-18 | 55 | 1015 | – | 368 |

| 82 | 24-39 | 63.35 | ||||||||||||||

| 900 | 36″ | 720 | 656 | 203 | 864.7 | 118 | 117.57 | 1050 | 24-33 | 300 | 254 | 8-18 | 85 | 1115 | 4-M33 | 713 |

| 1000 | 40″ | 800 | 721 | 216 | 956 | 142 | 129.89 | 1160 | 24-36 | 300 | 254 | 8-18 | 85 | 1230 | 4-M33 | 864 |