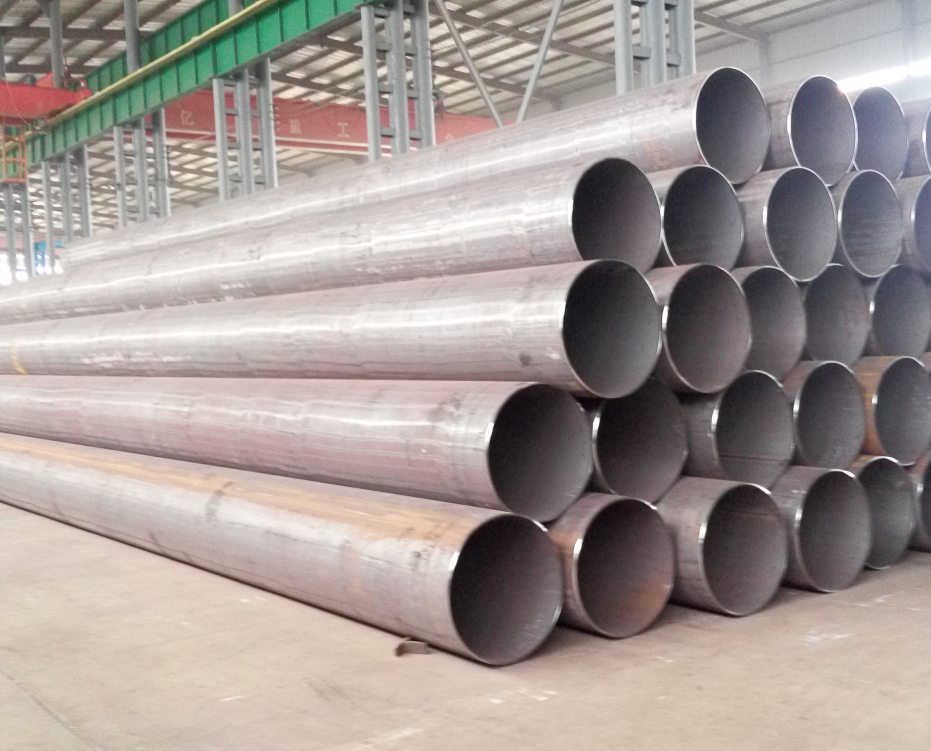

Welded steel pipe refers to a steel pipe made by bending and deforming steel strips or plates into circular, square, or other shapes, and then welding them together with joints on the surface. The raw material used for welded steel pipes is steel plates or strips.

Classified by weld shape It can be divided into straight seam welded pipe and spiral welded pipe:

1.Straight Seam welded pipes

The production process is simple, the production efficiency is high, the cost is low, and the development is fast.

2.spiral welded pipe

The strength is generally higher than that of straight seam welded pipes, and it can produce welded pipes with larger diameters using narrower billets. It can also produce welded pipes with different diameters using billets of the same width. However, compared to straight seam pipes of the same length, the weld seam length increases by 30-100%, and the production speed is lower. Therefore, smaller diameter welded pipes mostly use straight seam welding, while large-diameter welded pipes mostly use spiral welding.

Spiral seam welded steel pipes are divided into two types: automatic submerged arc welded steel pipes and high-frequency welded steel pipes.

a、 Spiral seam automatic submerged arc welded steel pipes are divided into Class A pipes and Class B pipes according to the pressure of the conveying medium. Class A pipes are generally welded with ordinary carbon steel Q235, Q235F, and ordinary low-alloy structural steel 16Mn, while Class B pipes are welded with steel such as Q235, Q235F, Q195, etc., and are used as low-pressure fluid transport pipes

b、 Spiral seam high-frequency welded steel pipe. There is no unified product standard for spiral seam high-frequency welded steel pipe, and it is generally made of ordinary carbon steel Q235, Q235F and other steel materials.

Types of Spiral welded steel pipe :

SAWH steel pipe, SSAW steel pipe, HFW Steel line pipe, HFW steel pipe, Galvanized Spiral welded steel pipe, 3PE coated spiral welded steel pipe

1.Spiral welded steel pipe materials: GR.B, X42, X52, ST37, ST52, S235JR, S355JR, SS400, SGP, STP G370 etc.

2. Spiral welded steel pipe standard: API 5L, ASTM A53, A139, A515, A252, A672 etc.

3. Spiral welded steel pipe specification:

OD: 219.1mm-3000mm.

WT: 4mm – 25.4mm.

Length: 6m – 18m.

4. End: plastic cap in the both end, pipe clamp.

5. Surface:oiled, black painted or varnish, galvanized, 3PE, FBE, or other epoxy coating.

6.Spiral welded steel pipe inspection:hydrostatic testing, ultrasonic testing, X-ray inspection.

7. Spiral welded steel pipe application: bridges, construction, water, oil and chemical industry.

Standards of Spiral welded steel pipe

| Standard | Specification | ||||||

| ASTM A53 | Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless | ||||||

| API 5L | Specification for Line Pipe(Two levels PSL 1 and PSL 2 of seamless and welded steel pipes for use in pipeline transportation systems in the petroleum and natural gas industries.) | ||||||

| A252 | Standard Specification for Welded and Seamless Steel Pipe Piles | ||||||

| A500 | Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes | ||||||

| BS EN10219-1 | Cold formed welded structural hollow sections of non-alloy and fine grain steels – part1: Technical delivert conditions | ||||||

| BS EN10219-2 | Cold formed welded structural hollow sections of non-alloy and fine grain steels – part2: tolerances dimmsions and sectional properties | ||||||